|

|

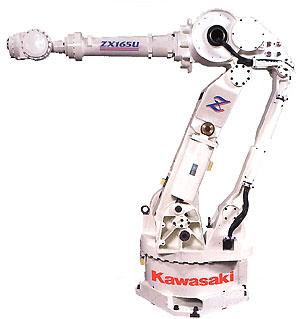

| All Electric AC Servo-Drive Heavy Cuty Industrial Robot |

| KEY FEATURES |

|

| Axes: 6 standard (7 optional)

Robot Arm Type: Articulated

Payload: 130-300 Kg (286-660 lbs)

Applications: Material Handling, Palletizing, Spot Welding,

Machine Tending, Packaging, Dispensing, Assembly, Racking

Basic Description: The Kawasaki ZX Series robots are

designed for heavy-duty payload applications requiring a

flexible work envelope and minimal dead space. The

patented Kawasaki Hybrid Link Configuration allows the

robot to turn backward, minimizing plant floor space

requirements. The new space saving design incorporates

a small footpring with integrated air piping and wiring. By

utilizing IP67 for the wrist, the ZX Series robots are able

to operate in the most severe environments. The ZX Series

robots provide a great variety of options for the customer,

having different arm combinations for various reaches,

speeds and payloads. |

|

| Special Features: |

| Common C Series Controller |

| Large Working Envelope |

| Heavy-Duty Cycle |

• High wrist torque and inertia capacity

• Maximum payload at entire work envelope

at full speed |

|

| Space Saving Design |

• Small footprint

• Kawasaki Hybrid Link Configuration

• Minimal dead zone |

|

| Production Advantages |

• Different arm combinations for various

reaches and payloads

• High speed capability

• Increased acceleration and deceleration rate

• High speed servo loop and all digital servo

control |

|

| Reduced Maintenance Costs |

• 10,000 hour maintenance intervals

• Modular design for quick repairs

• Brushless AC servo motor

• Common spare parts

• Fittings for simple lubrication |

|

|

|

|

|

|

|

| User Benefits: |

| Proven Reliability |

|

• Over 30 years of experience |

|

| User Friendly Programming |

• Simplified teaching method using multi-function

panel

• High level "AS" language for advanced

programming

• Menu driven software

• On screen diagnostics

• Automatic speed limitation in teach mode |

|

| Safety |

• E-stop button on multi-function panel and

controller

• Overtravel limits |

|

| Controller Features: |

| Kawasaki C Controller with 32 Bit RISC Type Microprocessor |

• 1 MB (4,000 steps) of memory

• Up to 4 MB (34,000 steps) of memory (opt)

• PC Card (1 MB or 4 MB) port for external

memory

• I/O: 32/32 channels, 24V DC

• I/O: expandable to 128/128 channels (opt)

• Networking capability (ControlNet, Ethernet, etc.)

• Allen Bradley Remote I/O

• Weld serial communication (opt)

• SLOGIC (internal PLC) (opt)

• Handheld LCD Multifunctional Touch Panel

comprising:

- Teach Pendant - Teach Pendant

- I/O Operation Displays - I/O Operation Displays

- Robot Function Menus and Operation - Robot Function Menus and Operation

- Status Displays - Status Displays

- Data Keyboard - Data Keyboard

- User I/O Soft Panel - User I/O Soft Panel |

|

|