|

|

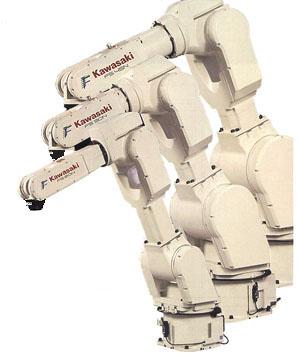

| All Electric AC Servo-Drive Heavy Cuty Industrial Robot |

| KEY FEATURES |

|

| Axes: 6 standard (7 optional)

Robot Arm Type: Articulated

Payload: 20-45 Kg (44-99 lbs)

Applications: Material Handling, Palletizing, Arc Welding,

Machine Tending, Packaging, Dispensing, Assembly, Racking

Basic Description: The Kawasaki FS 20/30/45 Series

robots are designed for medium payload appplications

requiring a flexible work envelope. the slim arm design,

simplified vertical alignment and robot pedestal mounted

joint 1 axis/motor allow the F Series robots to require less

plant floor space while having an extremely large work

envelope. The F Series robots provide a great variety of

options for the customer, having differend arm combinations

for various reaches and payloads. |

|

| Special Features: |

| Common C Series Controller |

| Large Working Envelope |

| Heavy-Duty Cycle |

• High wrist torque and inertia capacity

• Maximum payload at entire work envelope

at full speed |

|

| Space Saving Design |

• Small footprint

• Slim arm construction

• Minimal dead zone |

|

| Production Advantages |

• Different arm combinations for various

reaches and payloads

• High speed capability

• Increased acceleration and deceleration rate

• High speed servo loop and all digital servo

control |

|

| Reduced Maintenance Costs |

• 5000 hour maintenance intervals

• Modular design for quick repairs

• Brushless AC servo motor

• Common spare parts

• Fittings for simple lubrication |

|

|

|

|

|

|

| User Benefits: |

| Proven Reliability |

|

• Over 30 years of experience |

|

| User Friendly Programming |

• Simplified teaching method using multi-function

panel

• High level "AS" language for advanced

programming

• Menu driven software

• On screen diagnostics

• Automatic speed limitation in teach mode |

|

| Safety |

• E-stop button on multi-function panel and

controller

• Overtravel limits |

|

| Controller Features: |

| Kawasaki C Controller with 32 Bit RISC Type Microprocessor |

• 1 MB (4,000 steps) of memory

• Up to 4 MB (34,000 steps) of memory (opt)

• PC Card (1 MB or 4 MB) port for external

memory

• I/O: 32/32 channels, 24V DC

• I/O: expandable to 128/128 channels (opt)

• Networking capability (ControlNet, Ethernet, etc.)

• Allen Bradley Remote I/O or ControlNet

capability (opt)

• Weld serial communication (opt)

• SLOGIC (internal PLC) (opt)

• Handheld LCD Multifunctional Touch Panel

comprising:

- Teach Pendant - Teach Pendant

- I/O Operation Displays - I/O Operation Displays

- Robot Function Menus and Operation - Robot Function Menus and Operation

- Status Displays - Status Displays

- Data Keyboard - Data Keyboard

- User I/O Soft Panel - User I/O Soft Panel |

|

|